El lugar de encuentro para los profesionales de Die Casting

5 razones por las que no te lo puedes perder:

#1 Oportunidades de networking: haz contacto con profesionales líderes del sector, expertos técnicos y responsables de la toma de decisiones, incluidos los del sector de la fundición ferrosa, representados en el evento asociado Global Foundry Show.

#2 Perspectivas del mercado: Obtén valiosa información de mercado sobre la región, un centro creciente para la manufactura industrial.

#3 Comparación de productos: Compara una amplia gama de productos y servicios de los expositores internacionales. Valora sus características, especificaciones y precios para tomar decisiones fundamentadas de compra.

#4 Enriquecimiento de conocimientos: Participa en un dinámico programa de conferencias con destacados ponentes. Adquiere nueva información sobre nuevas tendencias, las mejores prácticas y los futuros desarrollos que influyen en el sector de la fundición a presión.

#5 Demostraciones prácticas: Acércate directamente a los expositores para conocer todas las capacidades de los productos y explorar posibles aplicaciones para tu negocio.

Descubre EUROGUSS MEXICO

EUROGUSS MEXICO traslada con éxito el concepto de un evento altamente especializado y establecido a nivel mundial, al mercado mexicano, latino y norteamericano. Toda la cadena de suministro de la fundición a presión presente en una exposición.

Los hornos de fundición son elementos indispensables en el proceso de fundición a presión. Permiten fundir con precisión materiales de fundición y aleaciones, que a su vez son la base de productos de alta calidad. Los avances tecnológicos han permitido mejorar la eficiencia energética y controlar con precisión la temperatura. Al mismo tiempo, los hornos de fundición contribuyen a la sostenibilidad fomentando el reciclaje de metales y reduciendo el uso de recursos primarios. En un mundo cada vez más consciente de los recursos, los hornos de fundición desempeñan un papel crucial en la fabricación de productos de alta calidad.

Paso 1: Fundición y materia prima

En general, hornos de fundición son componentes indispensables del Die Casting. Permiten la precisa fundición de metales y aleaciones. -Son la base de los productos de alta calidad-

La precisión es crucial en la industria de la fundición a presión, por lo que la garantía y el control de calidad desempeñan un papel importante. Para garantizar que las piezas de fundición producidas cumplen las normas de calidad más estrictas, se utilizan modernos métodos de ensayo, como rayos X, ultrasonidos y pruebas no destructivas. El uso de sofisticadas tecnologías de medición garantiza un control preciso de la exactitud dimensional y el acabado superficial.

Paso 4: Control de calidad

La precisión es crucial en la industria de la fundición a presión, por lo que la garantía y el control de calidad desempeñan un papel muy relevante.

La planificación y el desarrollo de procesos en la fundición a presión son cruciales para la fabricación de productos de alta calidad. El uso de software de última generación, la integración de los conceptos de la Industria 4.0 y la investigación y el desarrollo continuos son claves para aumentar la eficiencia y la calidad. Esto conduce a la industria hacia un futuro prometedor.

Paso 7: Desarrollo del proceso

La integración de los conceptos de la Industria 4.0, la investigación y el desarrollo continuos son claves para aumentar la eficiencia y la calidad. Esto conduce a la industria hacia un futuro prometedor.

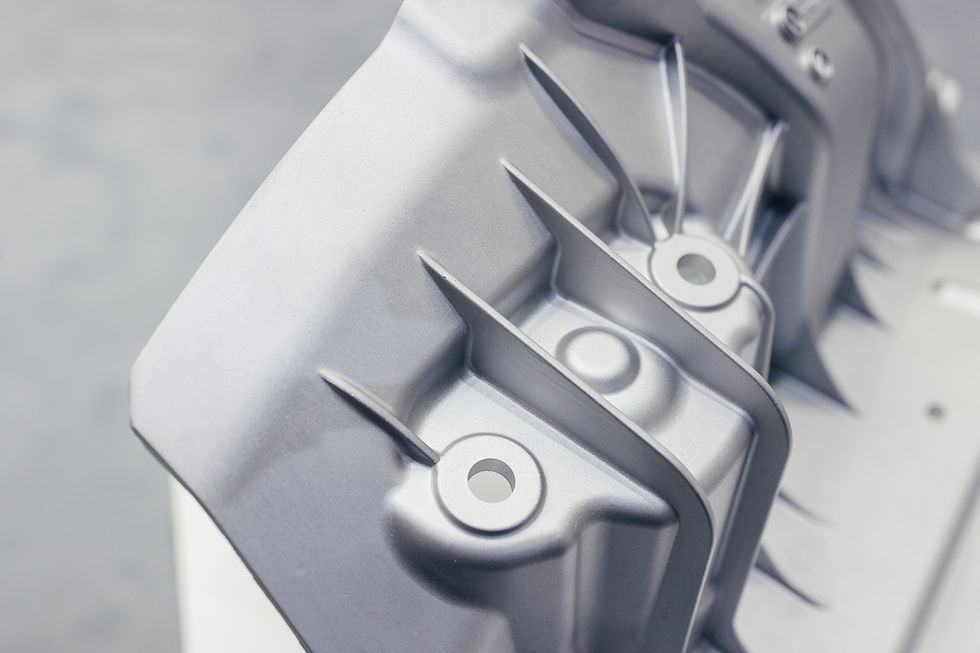

El proceso de fundición a presión es una compleja interacción de tecnología, precisión y eficacia. Desde la sofisticada máquina de fundición a presión hasta la periferia automatizada, pasando por el uso optimizado de los materiales de operación y la precisión de las herramientas, todos los detalles contribuyen a la producción de piezas metálicas de

alta calidad. Centrado en la sostenibilidad y el avance tecnológico, el proceso de fundición a presión sigue siendo una piedra angular de la fabricación moderna, en constante evolución para satisfacer las demandas de la industria.

Paso 2: Proceso de fundición a presión

Es una compleja interacción de tecnología, precisión y eficacia. Todos los detalles contribuyen a la producción de piezas metálicas de alta calidad.

El procesamiento subsecuente de las piezas fundidas en Die Casting es un proceso clave que garantiza la calidad y la funcionalidad. Mediante la integración de tecnologías innovadoras y prácticas respetuosas con el medio ambiente, las empresas ayudan a forjar un futuro mejor para la industria y el mundo entero.

Etapa 5: Procesamiento subsecuente de las piezas fundidas

Garantiza la calidad y la funcionalidad.

El tratamiento térmico y el acabado de las piezas fundidas son pasos cruciales para maximizar la calidad y el rendimiento de las piezas metálicas. Mediante el uso de hornos modernos, equipos periféricos de alta calidad y prácticas respetuosas con el medio ambiente, las empresas no sólo pueden fabricar productos de primera calidad, sino también cumplir con sus responsabilidades medioambientales. La combinación de calidad y sostenibilidad es clave para el éxito de la producción de piezas fundidas a presión.

Etapa 3: Tratamiento térmico y postratamiento de la fundición

Son pasos muy importantes para lograr la calidad y características deseadas de las piezas fundidas a presión.

La amplia aplicación de los productos de fundición a presión en diversas industrias ilustra su versatilidad y rendimiento. Desde la automoción a la industria aeroespacial, pasando por la medicina o la agricultura, entre otras, los productos de fundición a presión ofrecen soluciones personalizadas que satisfacen los exigentes requisitos de diferentes sectores. Gracias al avance de las tecnologías y a la innovación continua, los productos de fundición a presión seguirán desempeñando un papel clave en el panorama de la fabricación moderna.